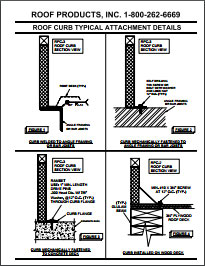

Download and view a PDF files of typical installation instructions for RPC-3 non-canted, canted and others below.

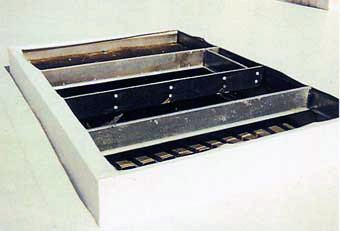

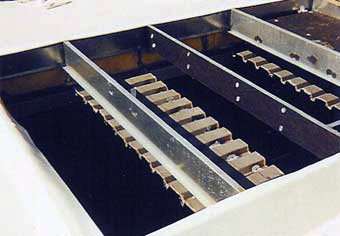

Roof Curb Installation Example

Conventional Construction process, below, which shows roof curb example installation series for RPC-3

1) Curb Installed on metal deck:

2) Insulation installed around roof curb on metal deck:

3) Rubber roof (single ply) installed around roof curb:

4) Decking cut out at supply and return areas only with no reinforcing angles needed:

5) Supply and return ducts installed onto curb cross channels:

6) Final installation of rooftop HVAC on curb: